Treatment method for tool radial runout of CNC milling machine

In the cutting process of CNC milling machine, there are many reasons for the machining error. The error caused by the radial runout of the tool is one of the important factors. It directly affects the minimum shape error and the machined surface that the machine tool can achieve under ideal machining conditions. geometry accuracy. In actual cutting, the radial runout of the tool affects the machining accuracy, surface roughness, unevenness of tool wear and the cutting process characteristics of multi-tooth tools. The larger the radial runout of the tool, the more unstable the machining state of the tool, and the more it affects the machining effect.

The radial runout of the tool during machining is mainly because the radial cutting force aggravates the radial runout. Therefore,

reducing the radial cutting force is an important principle for reducing radial runout. The following methods can be used to reduce radial runout:

1. Use sharp knives

Choose a larger tool rake angle to make the tool sharper and reduce cutting force and vibration.

Choose a larger tool relief angle to reduce the friction between the main tool flank and the elastic recovery layer on the transition surface of the workpiece, thereby reducing vibration. However, the rake angle and rear angle of the tool cannot be selected too large,

otherwise the strength and heat dissipation area of the tool will be insufficient. Therefore,

it is necessary to select different tool rake angles and relief angles in combination with the specific situation.

During rough machining, it can be smaller, but in finishing machining, in order to reduce the radial runout of the tool, it should be larger, so that the tool Sharper.

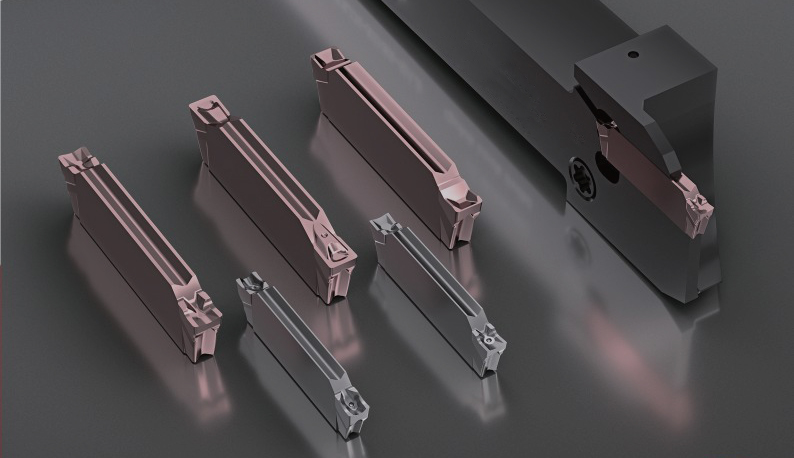

2. Use strong tools

There are mainly two ways to increase the strength of the tool.

One is to increase the diameter of the tool holder. Under the same radial cutting force,

if the diameter of the tool holder increases by 20%, the radial runout of the tool can be reduced by 50%. The second is to reduce the protruding length of the tool.

The larger the protruding length of the tool, the greater the deformation of the tool during processing.

In the process of continuous change during processing, the radial runout of the tool will continue to change,

resulting in workpiece If the machined surface is not smooth, the tool extension length will be reduced by 20%, and the radial runout of the tool will also be reduced by 50%.

3. The rake face of the tool should be smooth

During processing, the smooth rake face can reduce the friction of chips against the tool,

and can also reduce the cutting force on the tool, thereby reducing the radial runout of the tool.

4. Spindle taper hole and chuck cleaning

The taper hole of the main shaft and the collet are clean,

free of dust and debris generated during workpiece processing.

When selecting a processing tool, try to use a tool with a short extension length.

When feeding the tool, the force should be reasonable and even, not too large or too small.

5. The amount of cutting knife should be selected reasonably

If the cutting amount is too small,

the phenomenon of machining slippage will occur,

which will lead to the continuous change of the radial runout of the tool during processing,

so that the processed surface is not smooth.

When the cutting amount is too large, the cutting force will increase accordingly,

thus This will lead to large deformation of the tool, increase the amount of radial runout of the tool during machining, and also make the machined surface not smooth.

6. Use up-cut milling in finishing

Since the position of the gap between the lead screw and the nut changes during down milling, it will cause uneven feed of the table,

resulting in shock and vibration, which will affect the life of the machine tool, tool and the surface roughness of the workpiece.

During up-cut milling, the cutting thickness changes from small to large,

and the load on the tool also changes from small to large, making the tool more stable during processing.

Note that this is only used in finishing machining. Climb milling is still used in rough machining,

because the productivity of down milling is high, and the service life of the tool can be guaranteed. 7. Reasonable use of cutting fluid.

7. Rational use of cutting fluid

The aqueous solution with cooling effect has little effect on cutting force.

Cutting oil with lubricating effect can significantly reduce cutting force.

Due to its lubricating effect, it can reduce the friction between the rake face of the tool and the chips, as well as between the flank face and the transition surface of the workpiece,

thereby reducing the radial runout of the tool.

Practice has proved that as long as the manufacturing and assembly accuracy of each part of the machine tool is ensured,

and a reasonable process and tooling are selected, the impact of the radial runout of the tool on the machining accuracy of the workpiece can be minimized.